Oct 20 Canning Line Basics: Choosing the Right Equipment for Your Beverage Brand

Guide for growing breweries looking to scale up packaging operations

In today’s craft beverage industry, cans have officially claimed the crown. Lightweight, durable, recyclable, and favored by retailers and consumers alike, aluminum cans are now the go-to format for packaging everything from flagship IPAs to water and everything in between. For breweries scaling up from taproom sales or mobile canning services, investing in an in-house canning line can be a game-changing step toward growth, quality control, and brand presence. For energy drinks or water, embracing the aluminum trend can play into sustainability and branding opportunities that connect with audiences across North America.

At Prospero Equipment Corp., we’ve spent decades helping beverage manufacturers evolve their production and packaging systems. With premium canning and labeling solutions from our trusted partners like GAI and Makro, we support craft producers in building packaging lines that perform today and evolve for tomorrow. Here’s what to consider as you plan your next phase.

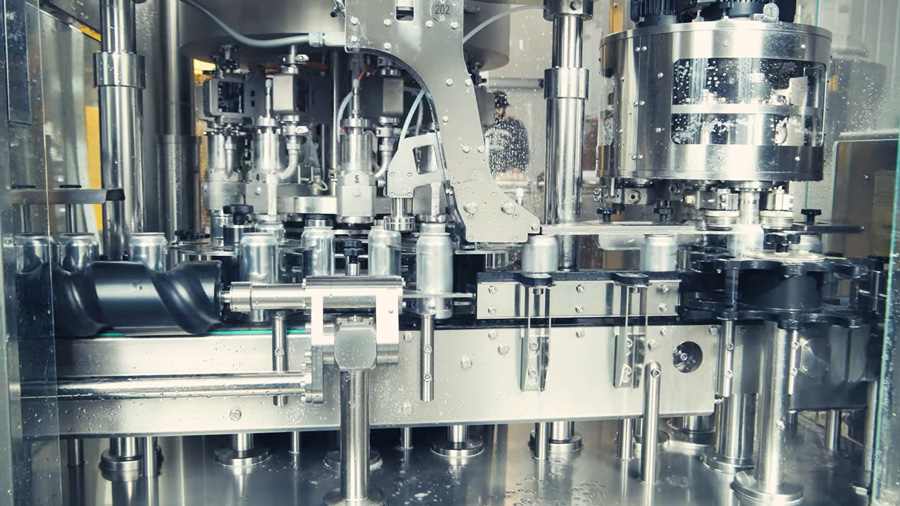

A closer look at the GAI MLE661, equipment built for breweries ready to take their canning to the next level

Depalletizing and Rinsing

Every canning line starts with clean, well-oriented cans. Depalletizers lift and stage empty cans onto the conveyor while maintaining orientation and minimizing damage. From there, cans are rinsed—typically with filtered air or ionized water—to eliminate dust and debris.

Features to look for include:

- Compact depalletizers for space-limited environments

- Adjustable systems to handle multiple can sizes

- In-line rinsers with nitrogen purging to reduce oxygen

Filling

Filling is the heart of the canning process, and precision here directly impacts product quality and shelf life. GAI’s counter-pressure can fillers are designed to preserve carbonation and minimize oxygen pickup during the fill. With options for both small-batch producers and high-speed operations, and still or carbonated beverages, GAI’s systems are scalable and built with industry-leading accuracy.

Benefits include:

- Counter-pressure filling for carbonation retention

- CO₂ purging pre- and post-fill to minimize dissolved oxygen

- Consistent fill volumes with minimal waste

- Seamless integration with downstream systems

Seaming

Once filled, cans are lidded and seamed. Quality seams are essential to prevent leaks, oxidation, or spoilage. GAI seamers offer tight tolerance control and durable performance.

Look for:

- Precision double seaming with automatic monitoring

- Compatibility with various lid types

- Integration with CIP for cleaning between runs

Watch South County’s GAI 3621 deliver 400cph of smooth filling and seaming

Labeling

Labeling is more than a branding exercise, it’s a functional step with major operational implications. Whether using pressure-sensitive labels, shrink sleeves, or innovative direct-to-surface decorations, your labeler must keep pace with your production line while delivering a flawless finish.

Our labeling systems deliver on speed and precision, with features like:

- Full- or partial-wrap label capability

- Servo-driven label application for consistent placement

- Tool-free changeovers for seasonal or rotating SKUs

- Compatibility with both paper and film labels

Among our labeling solutions, Prospero is pleased to be able to offer the Makro line, including Hot-Glue, Pressure Sensitive Labels (PSL,) Roll-fed, Cold-Glue, and the exclusive Actega – Signite decorating system for cans as well as bottles.

Note: If you’re utilizing exclusively pre-printed cans, you might be able to avoid the need for labeling equipment, but most breweries opt for the flexibility that inline labeling offers, even if some of their can stock is pre-printed.

Date Coding and Traceability

To meet legal requirements and retailer standards, cans must typically marked with production codes, best-by dates, or batch info. Prospero and other integrators (I’m realizing I’m not 100% clear on the role we play visa vie marking and coding) offer a variety of coding systems that integrate cleanly into any canning line, providing reliable marking at high speeds without downtime.

Pack Out and Palletizing

From here, your product is ready to be packaged and shipped. Depending on your volume, you may need:

- Snap-on or PakTech-style handle applicators

- Tray packers or shrink bundlers for multi-pack formats

- Case erectors, sealers, and palletizers to prepare product for distribution

Prospero can help you design a line that fits your current needs and allows for staged expansion.

Future-Proofing Your Packaging Line

The craft beverage industry is rapidly changing—not just in flavors and formats, but in packaging expectations, sustainability mandates, and branding demands. Your canning line should meet your needs today and set you up for tomorrow.

That’s where Makro Labeling stands apart. In addition to their advanced, modular labeling systems, Makro is the exclusive global equipment partner for Actega’s Signite decorating technology—a breakthrough solution gaining momentum for its combination of sustainability and cost efficiency.

Signite offers:

- Direct-to-surface decoration that eliminates label liners, adhesives, and backing materials

- Full recyclability, with no label removal required

- Premium finish with tactile and high-resolution effects

- Competitive economics compared to traditional labels and sleeves

This innovation positions Makro equipment as a powerful long-term investment for breweries looking to reduce environmental impact without compromising on branding or performance.

Whether your focus is increasing throughput, improving quality, or making your packaging more sustainable, choosing Signite-compatible equipment ensures you’re ready for the next evolution in craft beverage packaging.

At Prospero Equipment Corp., we help breweries bring their packaging operations in-house and up to speed. With over 50 years of experience and a portfolio that includes industry-leading brands like GAI and Makro, we provide end-to-end canning line solutions—from planning and configuration to installation, training, and ongoing support.

Whether you’re just getting started or preparing to expand your distribution footprint, Prospero has the expertise and equipment to help you scale up confidently.

Get in touch with us today to talk about building your next canning line.