Our wide range of brewing and brewery equipment can be fully customized to meet your needs.

Brewing & Brewery Equipment

We are proud to offer Brewery Equipment made from the finest stainless steel. Our wide range of beer brewing and brewery equipment can be fully customized to meet your specific needs- whether you need a complete design/ build for a new brewery startup or are upgrading pre-existing equipment in a small or large brewhouse.

From extensive brewhouse buildouts to fermentation, bottling, and packaging solutions- Prospero Brewing Equipment is the only resource you will need. We design, build, and install brewery equipment, tanks, and packaging solutions for pilot batch setups all the way to regional sized breweries. We pridefully serve the full spectrum of brewery sizes.

Brewhouses

The heart of every brewery lies within its brewhouse. This is where the beer acquires its unique qualities that effect the final flavor and character of the beer. We work with the client’s vision and defined brewing process to assist in planning, designing, and fully building out all sizes of breweries.

Beer Tanks

We use various types of beer and fermented beverage processing tanks specifically designed for the high standards of the brewing Industry. We have both Fermentation and Brite tanks for beer and other carbonated liquids.

Beer Can & Bottle Fillers

We have a wide range of customized beverage equipment for brewers, and breweries of variable sized production operations. Our specialty filling equipment can handle still, carbonated, spirits and viscous liquids. We have a range of filling machines that operate with a variety of container designs and closures.

Beer Bottle Closures

We offer a variety of closure options with different designs and styles for today’s Beer and Brewery production market. We have both the Semi Automatic, and Automatic options available. Some of the styles include: cork, crown cap, t-top, cork and cage, screw cap, and more.

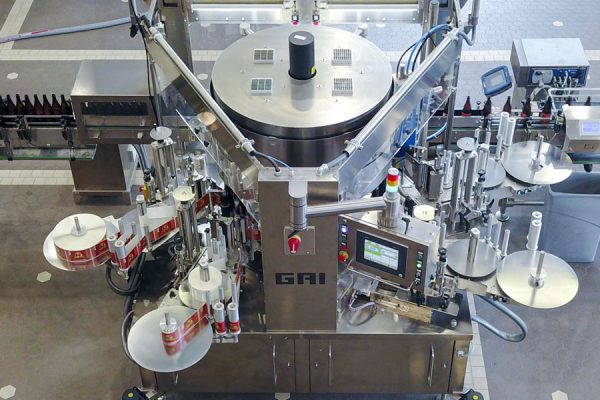

Beer Can & Bottle Labeling

We have the ability to label a wide variety of can and bottle shapes and sizes within the Beer Brewing & Brewery Industry. We utilize both Self-Adhesive and Glue Labelers.

Brewery Product Packaging

We offer high quality product packaging equipment for the beer brewing and brewery industry that include palletizers and depalletizers, case erecting, partition inserting, case packing, top sealing and weight check systems.