Oct 22 Scaling Up: When Is It Time to Invest in Automated Labeling Equipment?

For small and growing beverage brands, the path from hand-applied labels to a streamlined automated labeling line is a natural part of scaling up. Whether you produce wine, craft beer, spirits, or are part of the surging categories like canned cold brew, kombucha, infused seltzers, or functional beverages, the shift to automation can be a turning point in both brand presentation and operational efficiency. But how do you know when it’s time to make that leap?

Recognizing the Signs That You’ve Outgrown Manual Labeling

Early on, hand-labeling or using semi-manual applicators might be sufficient. Or perhaps you’re purchasing preprinted or wrapped cans for just one or two SKUs. Small batches and local distribution don’t always demand high-speed or consistency. However, as demand grows, manual labeling or purchasing pre-printed packaging can quickly become a bottleneck or weakness. Signs it may be time to upgrade include:

- Increasing Order Volumes: When your team spends more time labeling than producing or fulfilling orders, it’s time to consider automation.

- Quality Inconsistencies: Hand-applied labels can vary in placement or show bubbles and wrinkles, which can hurt shelf appeal.

- Expanding SKUs or Packaging Types: More product variations often require faster changeovers, higher precision, or the ability to label blanks instead of ordering premade packaging.

- Missed Deadlines: Struggling to meet delivery timelines because labeling slows down production is a clear sign of inefficiency.

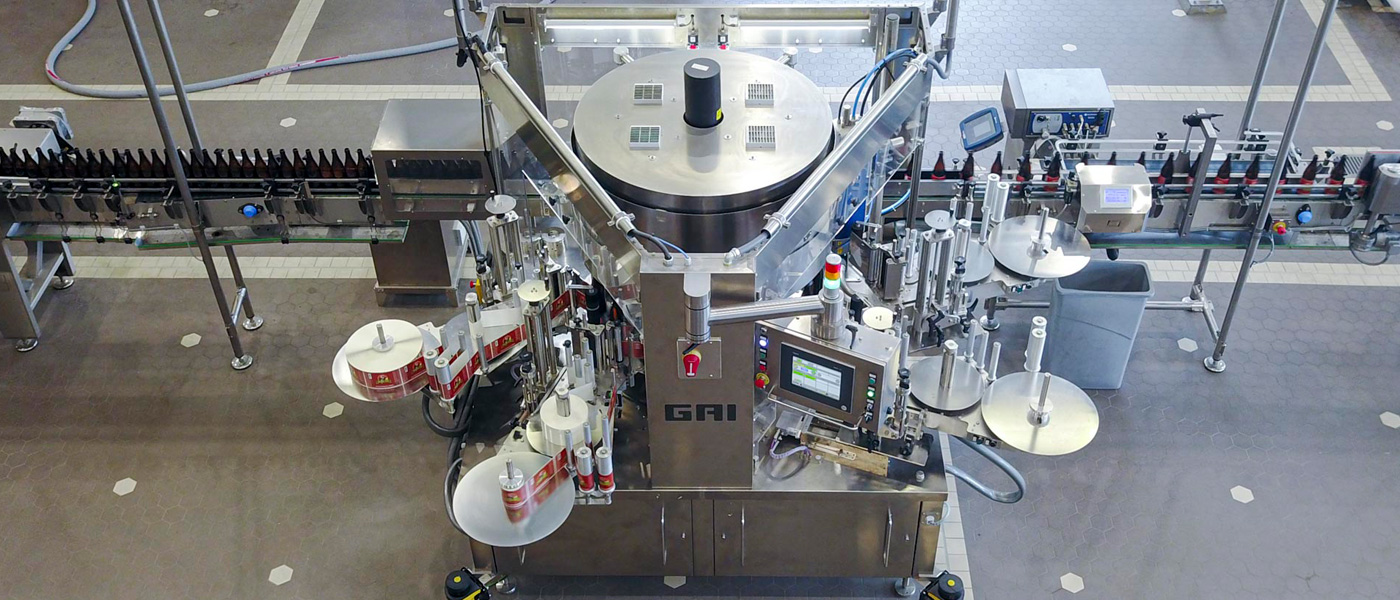

Why Automated Labeling Is a Game-Changer

Automated labeling equipment offers more than speed—it delivers consistency, professional presentation, and flexibility. A quality labeling machine can handle a range of container sizes and shapes, from standard wine bottles to sleek aluminum cans, without sacrificing precision. They can also allow for inventory gains and efficiency. For emerging categories like functional drinks and RTD cocktails, sharp label placement and tamper-evident seals are crucial to winning customer trust.

The Cost-Benefit Balance

While the upfront investment can feel significant for smaller brands, the return is measured not only in labor savings but also in brand reputation. Professional-looking packaging can elevate a product, helping it stand out on a crowded shelf or cooler. Moreover, automated systems reduce waste from misapplied labels and allow for higher throughput—critical as distribution scales to regional or national levels.

Customizing for Your Growth Stage

At Prospero Equipment Corp., we’ve spent over 50 years helping beverage manufacturers of every size scale their operations effectively. From compact, entry-level machines designed for smaller runs to fully automated systems for high-speed production lines, our team understands that each brand’s journey is unique. We work closely with wineries, breweries, distilleries, and producers in emerging beverage categories to find labeling solutions that fit today’s needs while leaving room for tomorrow’s growth.

When to Take the Next Step

If you’re consistently facing production slowdowns or see an opportunity to expand into larger markets, investing in automated labeling equipment could be the move that accelerates your success. As the beverage industry continues to evolve, brands that adapt their operations early often find themselves better positioned for the next wave of consumer demand.