Jun 02 The Perfect Crush Pad Set-up

Harvest season is when everything happens at once—and the equipment you rely on needs to do more than just keep up. For small and mid-sized wineries producing between 2,000 and 20,000 cases annually, efficiency and flexibility are essential. Whether you’re dealing with hand- picked grapes, machine harvested fruit, varying varietals, or tight crush pad space, your destemmer-crusher needs to deliver quality results without slowing you down or locking you into a rigid setup.

That’s where the right equipment makes all the difference. You need something that’s not just capable—but configurable. Not just powerful—but versatile.

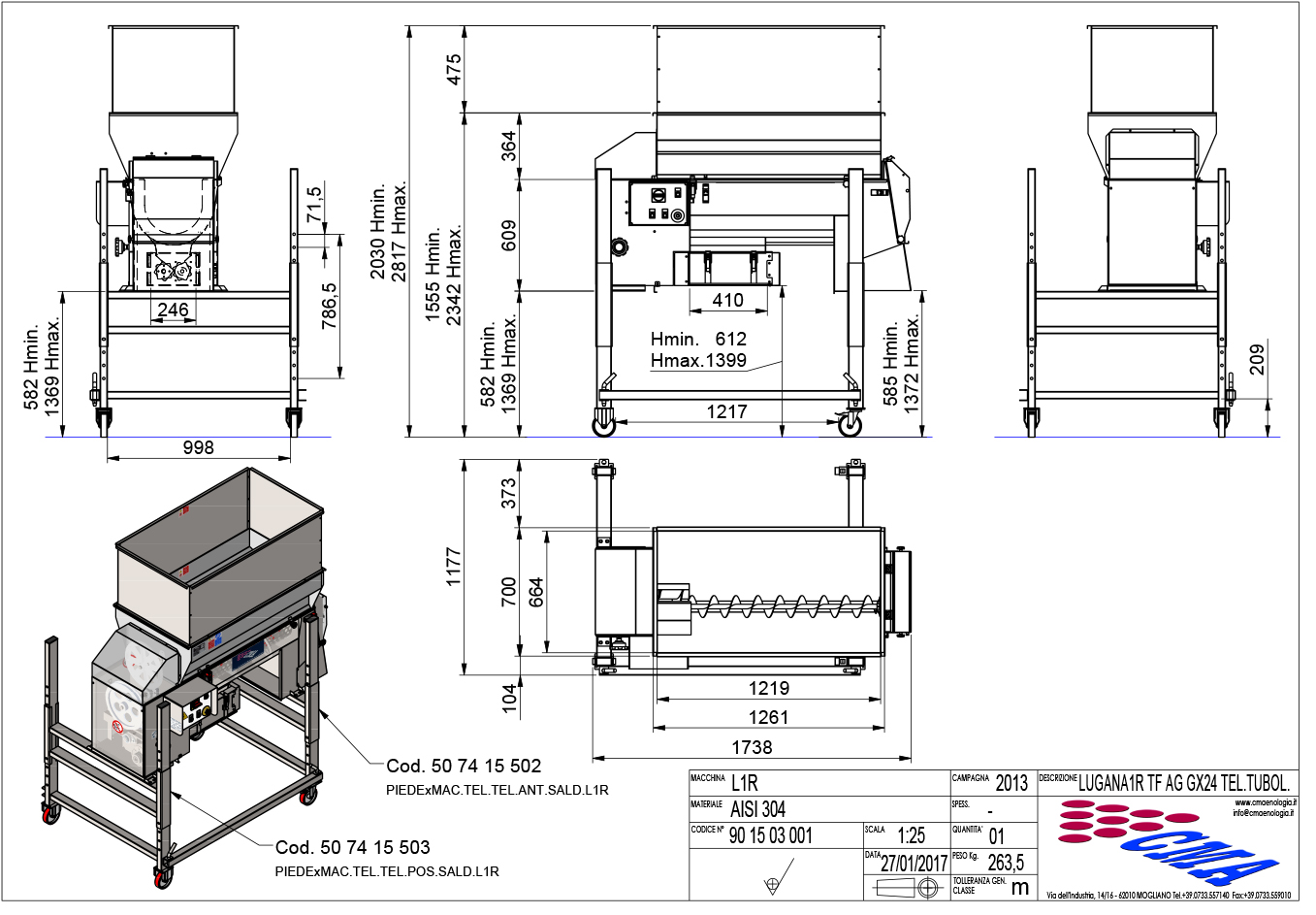

A Crush Pad Essential: Meet the Lugana 1R

At Prospero Equipment Corp., we’ve been supporting wineries for over 50 years, and we know how important the right tools are for maintaining wine quality from grape to glass. We also know how important productivity and efficiency is in the crunch-time of harvest season; that’s why we recommend the Lugana 1R as the perfect integrated destemmer-crusher for boutique and mid-size producers.

With a throughput of 1 to 6 tons per hour, the Lugana 1R is built for versatility. It features:

- Adjustable speed controls for both the grape infeed auger and destemming paddles

- Soft poly-tipped paddles to reduce maceration

- Multiple cage options, including stainless steel and food-grade plastic

- Rubber crushing rollers with hand-adjusted spacing to control crush levels

From hand-picked fruit to machine harvested fruit, the Lugana 1R is adaptable to your harvest style and production scale and maximizes the available space on your crush pad.

Built to Move, Designed to Flex

One of the most loved features of the Lugana 1R is its mobility and versaility. With locking caster wheels and telescopic legs, it can be repositioned or easily moved around. That’s a game-changer for small wineries working with tight layouts or staggered harvest schedules. The adjustable leg stand allows a winery to lower the unit down to work with a must pump or be raised up to destem the fruit directly into macro bins. It also has the ability to place a post sorting table under the Lugana 1R like our roll tech mini automatic grape sorting system. Versatility at its best!

Clean, Maintain, Repeat

Ease of cleaning is built into every component. The destemming drum, axle, and must gathering tank are all removable for fast, thorough sanitation between batches. Quick access points make daily maintenance simple and keep your workflow moving.

Roll Tech mini– An Affordable Option for Automatic Grape Sorting!

The Roll Tech Mini sorting table integrates seamlessly with the Lugana 1R destemmer/crusher units for gentle handling of hand-picked fruit. The system will easily roll underneath the lugana 1R (with leg stand) and sort out any green jacks, leaves or stems that made it through the destemmer. Its food grade roller system is adjustable and can be adjusted on the fly to ensure proper sorting of whole berries from waste material. With its low entry cost and automatic design which greatly reduces labor cost makes it a great solution for any small to mid-range winery.

And when you don’t need it, it simply rolls out of the way.

Need More Throughput?

The Lugana 1R is an excellent fit for smaller wineries but if anticipate needing higher capacity in the future, Prospero has you covered.

- The Lugana 2R steps up to 7–9 tons per hour, perfect for growing wineries or mid-size operations looking for increased efficiency. This unit can still be paired up with our roll tech mini to process at these speeds as well.

- For even higher capacity, the Lugana 3R delivers 12–20 tons per hour, ideal for larger commercial-scale wineries producing 50,000+ cases annually.

Whether you’re scaling up, future proofing or starting big, we have the right equipment for your production goals.

The Prospero Difference

As a long-time partner to the wine industry, Prospero Equipment Corp. delivers more than machines—we offer integrated solutions backed by decades of experience. From first crush to full-scale production, we’ll help you build a system that’s efficient, scalable, and tailored to your needs, your crush pad, and your unique workflow.

Ready to Take Your Crush Pad to the Next Level?

Get in touch with a Prospero Equipment specialist and let us help you configure the perfect setup for this harvest—and the next.

Corporate Office

123 Castleton Street, Pleasantville, NY 10570

Tel: +1 (914) 769-6252

Fax: (914) 769-6786