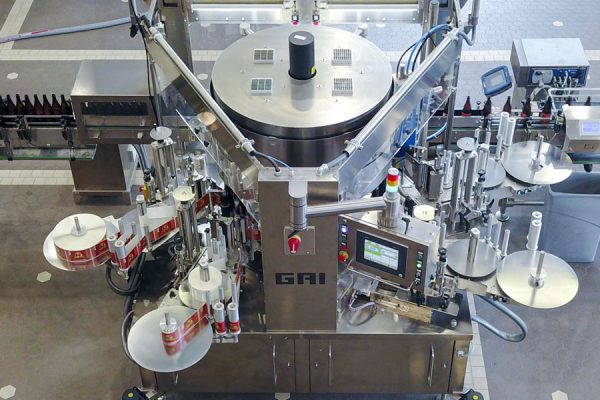

Our labeling equipment has the versatility to handle a wide range of bottle shapes and sizes along with multiple label configurations.

Labeling Equipment

Prospero Equipment has the ability to label a wide variety of bottle shapes and sizes within the beverage industry with our selection of self-adhesive and glue labeling machines.

Self-Adhesive Labelers

Streamline your beverage labeling process with Prospero Equipment’s Self-Adhesive Labelers. Embrace precision and speed in label application.

Glue Labelers

Optimize your beverage branding strategy with Prospero Equipment’s Glue Labelers, ensuring seamless label application and elevated product presentation.