CAN LIDS DISTRIBUTOR WITH GAS INJECTION

The lid storage locations are placed on the support base of the entire distribution group. Lid release devices are installed below the storage locations. The release device, controlled by a pneumatic piston, holds the entire column of lids and releases them one at a time. The lid is held by the translator, which subsequently moves it above the can. When the translator has transported the lid above the can, a pneumatic gripper picks up the lid. The translator retracts and the lid is placed with a slight pressure on the can.

Injection of neutral gas is essential to substantially reduce the quantity of oxygen present in the space between the liquid and the lid. While the lid gripping device is in the raised position, neutral gas begins to flow through the special diffuser above the can. The flow continues and the gripping device rests the lid on the can with a light load. The gas pressure is adjustable in order to obtain the most suitable flow according to the production speed. The neutral gas dispenser and inlet device can be easily sterilize to preserve the best hygienic conditions.

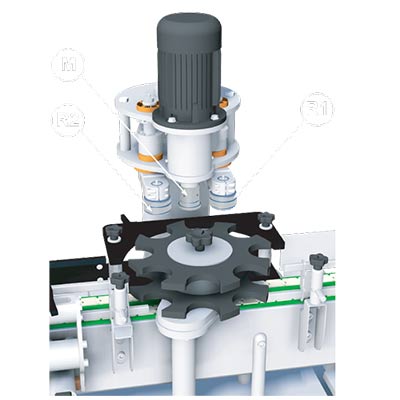

Seaming

The can is transported by the star under the rota-ting chuck M and raised by the piston. The chuck, perfectly positioned in the internal profile of the lid, drags the can in rotation, while it is held in position by the star and the counter-star. The two seaming devices, R1 and R2, controlled by mechanical cams, perform the first and second closing operations in rapid succession. At the end of the operation, the piston is lowered and the star transfers the can onto the load cell and then onto the conveyor belt.

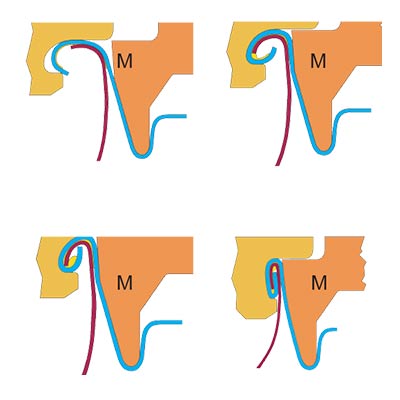

The seaming operation takes place in two distinct stages, this guarantee perfect sealing. The 1st operation roll R1 is mechanically brought against the lid, held by the M chuck, and then dragged into rotation.

1. Start of 1st operation seam formation

2. Partially formed 1st operation seam: forming the end curl under the flange

3. Finished 1st operation seam formation The roll R1 moves away and the 2nd operation roll R2 stars its function; this last is pressed against the first seam to complete the operation and finally seal the lid on the can.

4. Finished 2nd operation seam formation: seaming completed.

After the seaming of the lid, the star, that moves intermittently, moves the can on the load cell and then on the conveyor belt. If the weight is outside the pre-set values, the can passing in front of an expeller, it is pushed out from the conveyor belt and dropped into a special collecting container. Use the sample weight included in the supply to check the correct load cell detection.