Mar 01 Prospero and Barison Launch Groundbreaking Continuous Distillation Still

Prospero Equipment Corp. and Barison Industry have unveiled the Supreme Continuous Still, a groundbreaking craft distillation system that seamlessly combines the precision of continuous distillation with the artistic flair and flexibility of pot distillation stills.

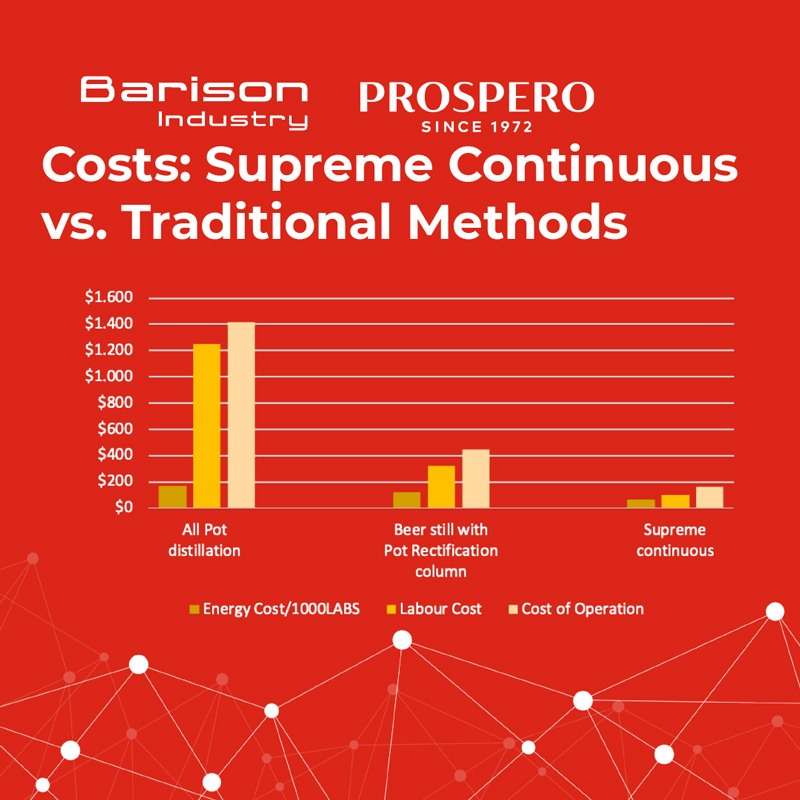

Distillation Revolution: New ‘Supreme Continuous’ System Slashes Costs by 38%, Maximizes Extraction Control

The inventive system allows for unlimited control over the extraction of heads and tails, ensuring proof variability while upholding consistency. Moreover, the new continuous still can cut relative distillation costs by up to 38% when compared to traditional systems equipped with a beer still and doubler. This reduction takes into account workforce requirements and energy consumption considerations. The Supreme Continuous is consistent, efficient, and has impressive throughput rates with minimal oversight.

Efficiency Elevated, Oversight Minimized

The Supreme Continuous is an automated distillation still. It transforms distillation, minimizing manpower and maximizing efficiency. This cutting-edge system, with advanced automation, seamlessly manages the entire process, freeing distillers from constant supervision. Human errors are eradicated, ensuring a smooth and precise operation. With recipe storage capabilities, distillers can effortlessly craft a diverse range of high-quality spirits at the touch of a button.

Flexible Distillation and Customization Capabilities

Distillation rates begin at 3 gallons per minute (GPM) but can be tailored to significantly higher rates if desired. The system addresses regulatory concerns by allowing for the extraction of ethyl carbamate with the tails fraction, ensuring a safe and compliant end product.

The core setup of the continuous distillation still includes a stripping column, separating alcohol and flavor components from spent grain and water, and a combined rectifying and fractionating column. The latter not only distills the product to the desired strength but also features multiple ports for drawing off specific quantities of heads and tails. These separate draws, each with dedicated coolers, offer unparalleled flexibility, enabling the production of a diverse range of high-quality distillates previously achievable only through pot stills.

Enhanced Capabilities

For those looking for enhanced capabilities, a three-column version is available, incorporating an additional rectifying column capable of producing high-quality neutral grain spirits and vodka.

Extreme Energy Efficiencies

The Supreme Continuous is incredibly efficient, with steam only required in the stripping column. The fractionating column is powered by overhead vapor from the stripping column, and if equipped with the third rectifying column, it also utilizes vapor from the fractionating column. The result is a system three times more energy-efficient than pot distillation and nearly twice as efficient as conventional beer stills with pot distillation or doubler distillation.

This new distillation system, the Supreme Continuous, seamlessly blends product flexibility and quality with unparalleled energy efficiency and labor efficiency, making it an asset for both emerging craft distilleries and established ones looking to elevate product quality and operational efficiency to new heights.

For more information, contact Prospero Equipment today!