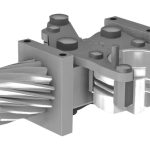

The bottles are gripped around the neck by a clamp, and rapidly turned upside-down by means of a rack and pinion system. The speed of this system enables longer cycles with the same number of clamps. The nozzle penetrates the bottle neck by 70mm; this depth prevents any interference between the injected water and the backflow. The injected water must be sterilized by microfiltration. As an alternative, the water can be ozonized, which will also perform a sterilizing action. The rinsing liquid is recovered in a closed circuit, keeping the machine dry during the normal working conditions. Bottles can also be “seasoned” by recirculating the appropriate product. This means that a bactericidal liquid can be used to completely sterilize the inside of the rinser, using the dummy bottles supplied with the machine.

Rinsing

Rinsing & Blowing

In this case the nozzle penetrates the neck of the bottle by 75 mm; this depth prevents any swirling in the neck, making the blowing more efficient. The injection of sterile water is followed by a series of blasts of air which has also been sterilized by microfiltration. The presence of the bottle sets up the machine for the opening of the injector, but the actual injection of the water or air is controlled by external cams, which can easily be modified to increase or reduce injection times. The water and air circuits are completely separate. Forced draining alternated with draining by gravity allows for better drainage of the water, minimizing the residue in the bottle and the consumption of air. The two options/steps can also be used differently, for example by injecting first air and then nitrogen. The height is standard electrically adjusted.