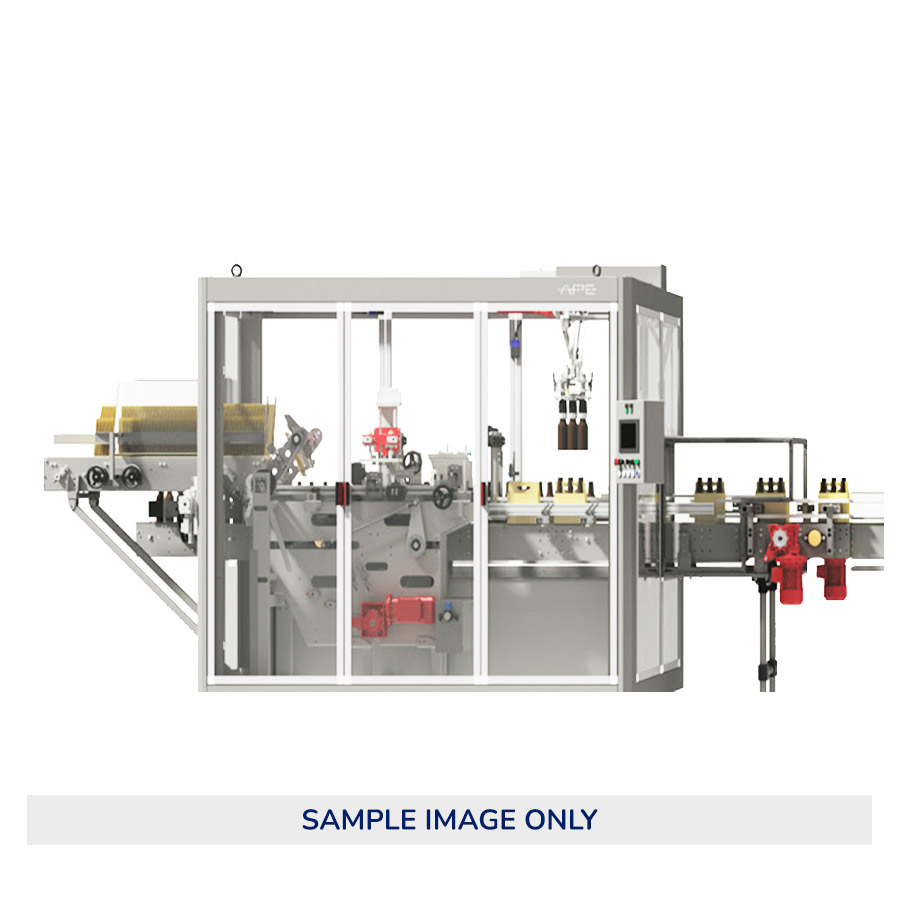

Carrier 200 – Carrier Erector/Packer into 4, 6 or 8 Pack Carriers

Automatic Packaging Machine Designed for Carrier Erecting and Bottle Packing

New and innovative packaging solution, it merges in a single machine all carrier erecting and packing operations. CARRIER 200 overcomes manual operations with its compact frame, affordability and high performance. CARRIER STANDARD 200 is the perfect packaging solution for every craft beverage or packaging facility.

Composed of:

Carrier Erecting Unit

Provides 4/6/8 pack carrier erecting and transfers the empty carrier to in-line carrier packer.

The easy-load carrier magazine ensures a continuous carrier carton supply to the erector.

“Teardrop” synchronized and servo-controlled movement design allows carriers to feed to the opening station. Using a dual vacuum grippers system, lower grippers hold the carrier firmly, while upper grippers pull the carrier open.

TECHNICAL DATA:

Carrier Dimensions:

- 4/6/8 pack carrier.

- Length: Min. 125 mm (5 inches) Max. 290 mm (11.5 inches)

- Height: Min. 180 mm (7 inches) Max. 300 mm (11.8 inches)

- Width: Min. 110 mm (4.3 inches) Max. 165 mm (6.5 inches)

- Cell: bottle diameter + 4 mm

Bottle Dimensions:

- Diameter: Min. 50 mm Max. 80 mm

- Height: Min. 180 mm Max. 300 mm

- Productivity: 1,700 cycles/h

- Productivity may vary in relation to different product formats.