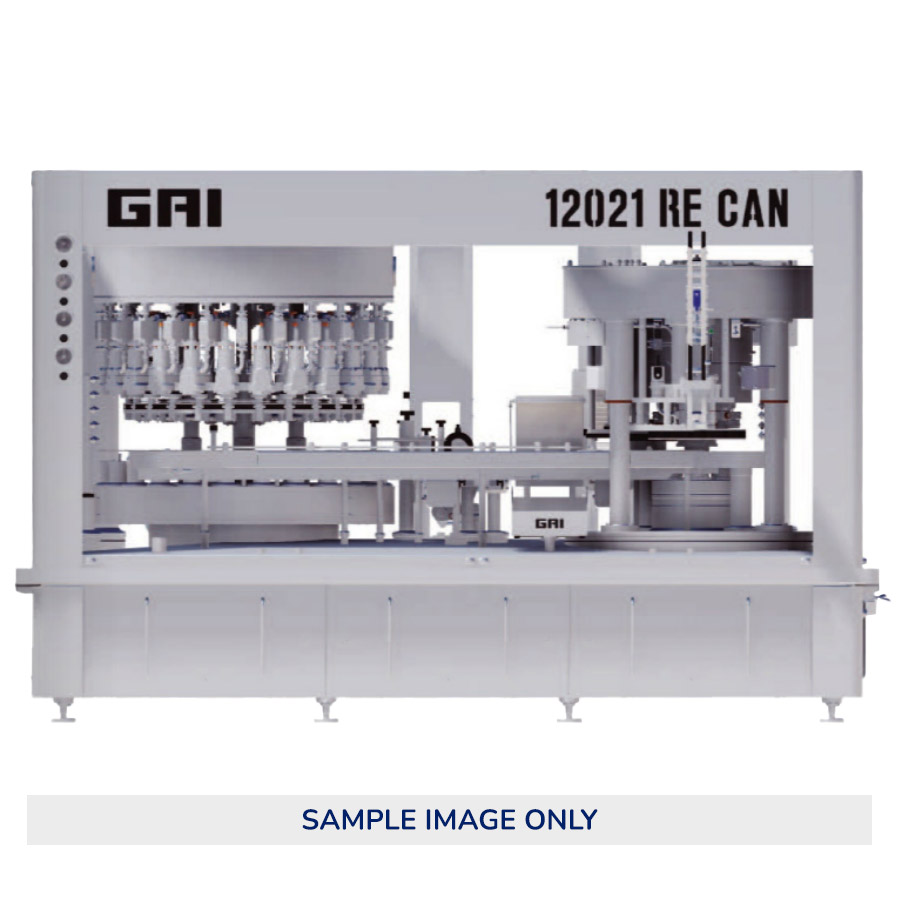

GAI 12021 RE CAN – Electro-Pneumatic Filler, Seamer Up To 12,000 Cans Per Hour

GAI 12021 RE CAN – Automatic monoblock composed of Stainless steel with Roof type Autocleaning slanted Inox Frame

up to 12,000 cans per hour

Suitable for canning bottling products from 0 to 4 Bar working pressure. The GAI 12021 FE CAN automated monoblock features a high pressure electro-pneumatic volumetric can filler on a 24 valve rotary turret. Featuring a 3 head rotary GAI seamer. The ability to have nitrogen injection for canning still products, is available upon request.

[1] High Pressure Volumetric Filler

Volumetric filler with 24 electro-pneumatic valves, with annular vessel, for aluminum cans.

Each valve includes:

– Magnetic-inductive flowmeter to check the filling volume.

– Pressure transducer to monitor the pressure in the can (the valve does not fill if the bottle does not reach the tank pressure).

– Electro-pneumatic valve for the injection of gas for the flushing of the cans.

– Electro-pneumatic valve for flushing gas discharge.

– Electro-pneumatic valve for gas discharge during the filling phase.

– Electro-pneumatic valve for the degassing phase.

– Double-acting electro-pneumatic pedestal to open / close the liquid circuit.

The volumetric filling valve avoids any return of the product into the tank, avoiding any possible contamination and oxidation of the product inside the tank. The filling cycle is set through the control panel and it does not require any manual intervention on the filler, depending on the capacity of the container to fill. Every valve has a dummy can for the cleaning and sterilization of the filler. The dummy cans are assembled on the filler, with automatic positioning and centralized discharge. All circuits are canalized, and the filler has a sterilizing CIP circuit.

The valve can operate with a pressure up to 4 Bar.

The filler has an analogical level feeler suitable to administrate the feeder pump inverter (the pump is not included in the price).

The gas pressure in all circuits is automatically controlled by the PLC.

The filler is equipped with external washing of the filling valves.

Cans lifting pedestals are pneumatics with cam return and automatic lubrication.

Filler height electric adjustment.

2) 4-Head GAI Rotary Seamer.

Before the application of the lid, the “bubble breaker” device eliminates excess foam and any surface bubbles that could lead to oxidation of the product.

The application of the lid is carried out with transfer star. Before receiving the lid, gas is injected between the can and the lid, ensuring the elimination of all the air present in the headspace of the can.

The gas pressure in the bubble breaker and lid distribution are separately adjustable and both circuits are fully washable.

For non-carbonated products, a liquid nitrogen dispenser (optional) can be inserted before the lid is distributed.

The lid is fed via a slide with a manually loaded vibrator (length about 2 meters).

The format change is quick and easy thanks to a quick release system of the seaming roll holder arm.

All crimping operations are carried out through sturdy mechanical cams in an oil bath, ensuring precision and reliability over time.

The second seamer operation can be excluded automatically from the control panel for a correct verification of the first operation seaming.

The seamer is equipped with external washing of the closing heads and the lid feeding star.

The inlet and outlet of the cans are parallel, on the same side of the monoblock.

Cans entry through infeed screw. Tangential exit from the filler with transfer chain to the seamer.

Equipped for a type of aluminum can and a type of lid.

Description

TECHNICAL DATA:

- Production Speeds: 12,000 cans per hour.

- Suitable for canning bottling products from 0 to 4 Bar working pressure.

- Safety guards in accordance with CE standards with tempered glass doors.

- Universal infeed screws.

- Sides motor adjustment in filler inlet.

- Electrovalves kit to switch gas and washing liquid entrance and discharge liquid of the circuit after washing cycle.

- Inlet gate-doser with inlet bottle jamming photocell and outlet anti-jamming photocell to adjust the bottle flow and possibly disable any malfunctioning filling valve.

- PLC and operating terminal (touch screen).

- External washing of cans (before the exit of the monobloc).

- Electrical height adjustment of all stations.

- Can Diameter: 50 – 73 mm

- Output: 4000 liters/hour (Beer) (1056 gallons/hour)

- Speed: 3000 -12000 cans/hour (based in 0.33 Lt. cans)