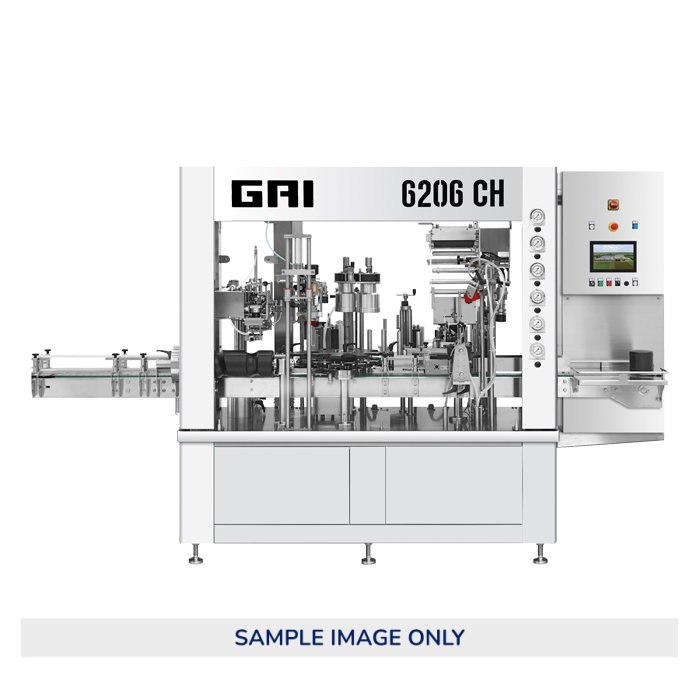

GAI 6206 CH – Automatic Foil Crimper, Labeler Up To 1,800 Bottles Per Hour With Foils 1,200 Bottles Per Hour With Polylaminate Capsules (Optional) 2,500 Bottles Per Hour With Heat Shrink Capsules (Optional)

GAI 6206 CH – Automatic Monoblock composed of Stainless steel for Champagne Bottles

[1] Capsules Dispenser for Sparkling Wine Foils. Extraction system using needles and air blow expulsion. Complete with cork detecting photocell, neck centring device and press cap piston. (optional arrangement for tin, polylaminated and shrink-wrap foils)

[2] Electronic System for Personalized Champagne Caps with Optical Centring (spot).

[3] Double Pneumatic Head for Preparation of 4 Pleats and Champagne Capsule Sleeking.

[4] Linear Labeler for Pressure Sensitive Labels with:

• Second orientation for spot on capsules.

• Station for body label with height adjustment.

• Station for back label with height adjustment.

• Station for champagne collar with height and horizontal adjustment with vertical descending.

Variable step infeed screw bottles inlet.

Machine supplied with security guards according to CE standards.

Labelling station and monoblock management centralized from the control panel with touch screen (possibility to save bottles format).

8 places star for optical centring and champagne capsule sleeking.

Equipped for one type of cylindrical bottle

Machine with 0.3hp conveyor and collecting plate of 500 mm.

Description

TECHNICAL DATA

Production Speed:

- Champagne capsules: 800-1,800 bottles/hour (no spot orientation)

- Polylaminated and tin foils: 800-1,200 bottles/hour

- Shrinking capsules: 1,000-2,500 bottles/hour

- Labels up to a maximum of 300 mm on cylindrical bottles

- Paper passage 190 mm and blade 100 mm for label and back label station

- Paper passage 220 mm for collar band station

- Label application tolerance ± 1 mm (on cylindrical bottle)

- Maximum number of label dispensing stations 3+1

- Label roll with inside diameter 76 mm and outside diameter 280 mm

- Height adjustable stations, between 10 and 150 mm from the bottom of the bottle

- Possibility to install a marker with thermal transfer on back label

- Possible station for affixing a second back label or mark. Support for vertical and angle adjustment

- Suitable for cylindrical and tapered bottles, maximum taper 1,5°

- Bottle diameter from 60 to 115 mm (optional from 50 to 60mm)

- Bottle height from 230 to 400 mm with caps dispenser

- Bottle height from 170 to 400 only labelling

- Roller for bottle rotation height = 100 mm, carriage = 125mm