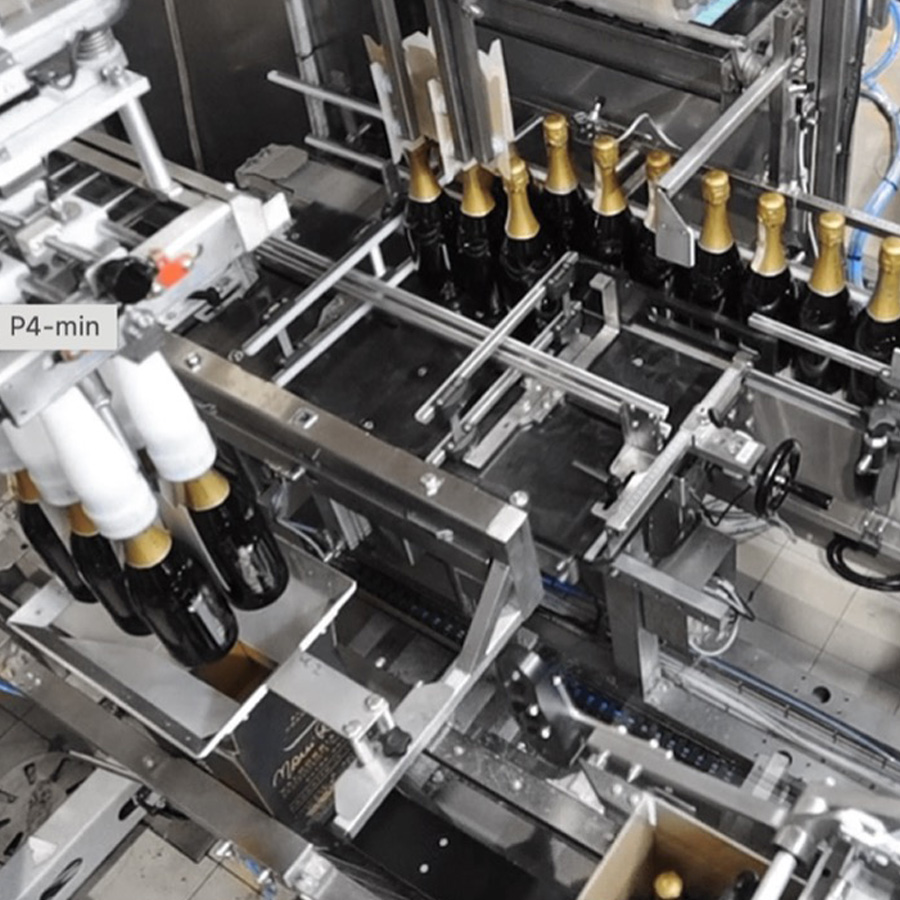

TRIO – Case Erecting, Bottles Packing, and Bottom Adhesive Taping

Automatic packaging machine designed for case erecting, bottles packing and bottom adhesive taping

Innovative packaging solution that blends in a single machine all packaging end of line tasks as RSC – AMERICAN TYPE CASE erecting, bottles case packing and bottom adhesive taping.

TRIO packaging machine overcomes manual operations and goes one better current solution which require more machines and space. Within its only 6m2 footprint, affordable and performing, TRIO is the workhorse machine designed for beverage industry.

Composed of:

- CASE ERECTING UNIT: Provides squared, well-sealed cases to the packing unit. Vacuum grippers ensure proper case transfer

from case magazine and smooth case opening. After case forming operation, specific device provides bottom flap folding. - CASE PACKING UNIT: Provides product line up and placement into case.The bottles/carriers conveyor ensures continuous

product feed to the picking platform. An horizontal transfer device arranges the precise number of bottles to be packed in. Cases,

coming from erecting unit, are transferred to the packing station. Dedicated packing head picks up and places product inside the

case. A special centering device provides with follow through packing operations to assure gentle product handling and labels

integrity. - CASE SEALING UNIT: The pacer-belt transfer automatically feeds cases to the sealing station. Dedicated devices provide

bottom flaps sealing by adhesive tape.

PRODUCT TECHNICAL FEATURES:

- Case dimensions:

- Length: Min. 190 mm Max. 440 mm

- Height: Min. 165 mm Max. 385 mm

- Width: Min. 140 mm Max. 330 mm

**Dimension limits may vary in relation to different product format.**

PERFORMANCE:

- 3,000 Bottles Per Hour for a 750 ml cylindrical bottle format in case of 6 or 12 bottles.

- Productivity may vary in relation to different product format

- Productivity may vary in relation to client layout design

- Technical specifications may be adjusted to each country requirement