Sep 16 Essential Equipment for New Winemakers: Wine Bottling and Labeling

For new winemakers, understanding the right equipment for bottling and labeling is crucial to producing quality wine efficiently. This guide will walk you through various options, from small-scale semi-automatic setups to larger automatic systems, helping you make informed decisions for your winery.

Semi-Automatic Equipment for Small-Scale Production

For more details, begin watching at 0:21. Let’s begin with semi-automatic equipment suitable for small-scale production. These setups typically include rinser-blower units, gravity-style fillers, corking machines, and labeling equipment. The process starts with rinsing and blowing bottles, which can be done with water, air, or inert gases to reduce oxygen exposure.

Wine bottle filling is accomplished using gravity fillers available in 4, 6, or 8 spout configurations, offering easy operation and adjustment with speeds ranging from 400 to 650 bottles per hour (BPH). Corking follows, utilizing machines with built-in sensors for precise cork placement and options for gas injection or vacuum sealing. Finally, labeling and capsule application are handled by bench-top labelers, heat shrink capsule applicators, or spinner versions for different capsule types.

Stepping Up: The GAI 600 Semi-Automatic Machine

For wineries looking to increase production, the GAI 600 semi-automatic machine offers a stepping stone between small-scale and fully automatic systems. This 12-spout filler-corker unit can handle up to 1,000 BPH, making it ideal for wineries producing around 3,000 cases per year. For more details, jump to 3:07.

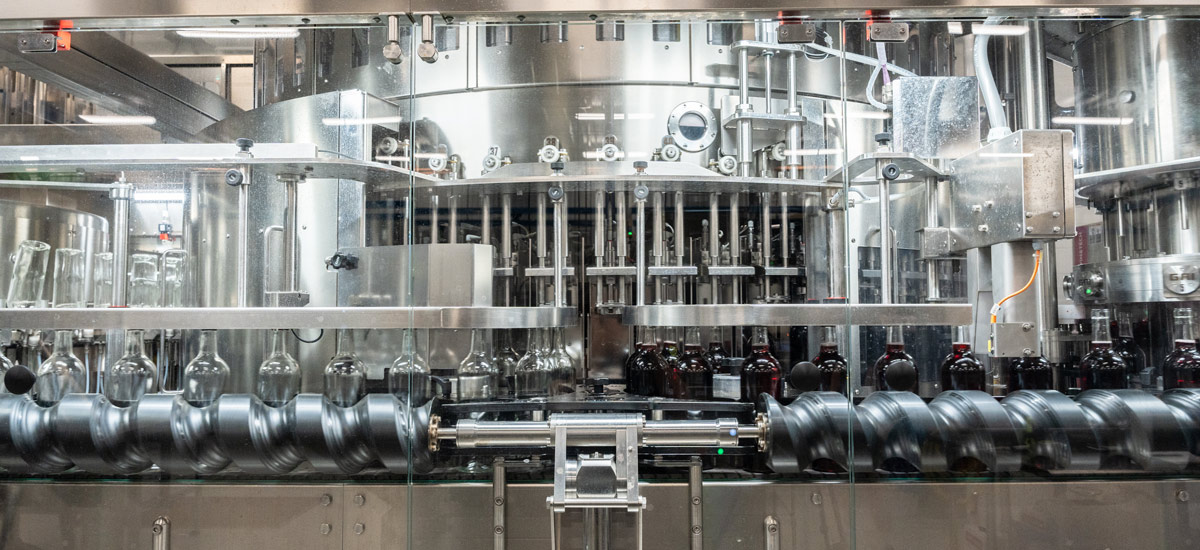

Automatic Capsule and Labeling Equipment

Jump to 4:05 for more information. Complementing the filling and corking equipment, automatic capsule and labeling equipment form an essential part of the bottling line. These separate monoblocks handle capsule application, and labeling, with speeds matching or exceeding the filling equipment, often reaching up to 2,500 BPH or more.

Oxygen Management: A Key Consideration

Throughout the bottling process, oxygen management plays a crucial role in maintaining wine quality and extending shelf life. Modern automatic systems are designed with multiple gas injection points before filling and corking/capping to minimize oxygen exposure, ensuring your wine reaches consumers in optimal condition. Begin at 6:05 for full details.

Choosing the right bottling and labeling equipment depends on your production scale, budget, and specific needs. From labor-intensive semi-automatic setups to fully automatic lines, there’s a solution for every winery size. Ready to equip your winery with the perfect bottling and labeling solution? Get in touch with Prospero Equipment Corp. today. Our experts will help you select the ideal equipment to streamline your production and ensure your wine reaches consumers in pristine condition. Don’t wait – take your winemaking to the next level with Prospero!