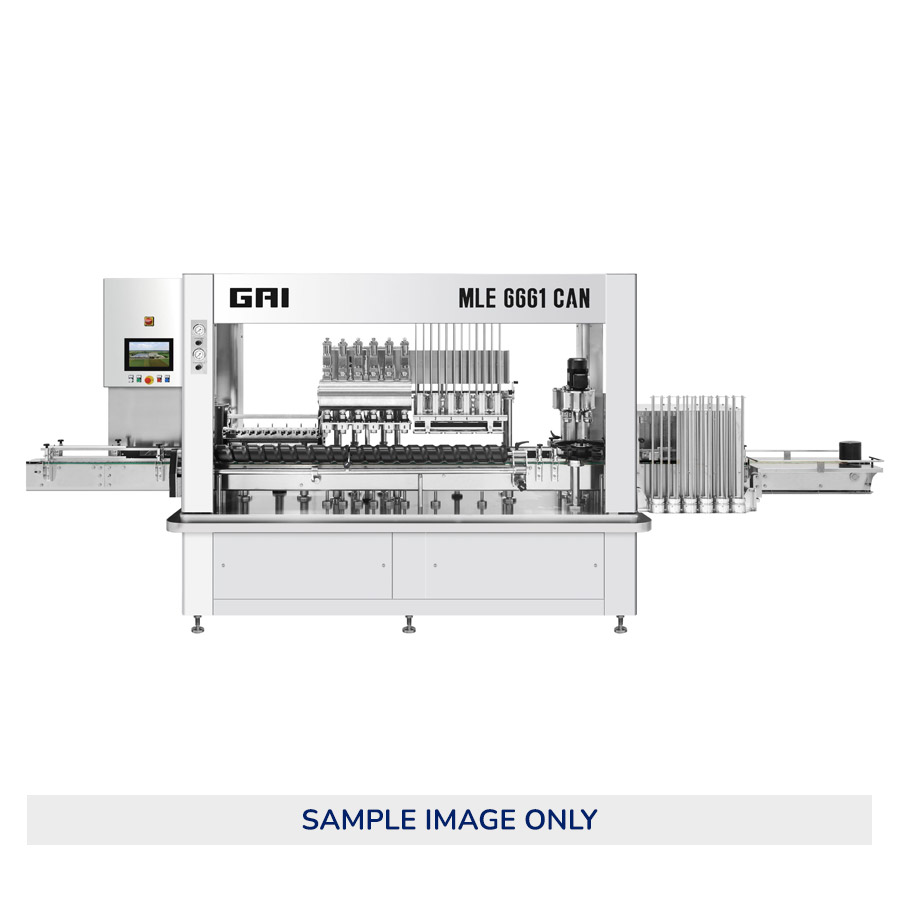

GAI MLE 6661 CAN – Rinser, Electro-Pneumatic Filler, Lid Dispenser, Seamer, Weight Checker, Post Rinser Up To 1,600 Cans Per Hour

GAI MLE 6661 CAN – Linear Automatic Monoblock composed of Stainless steel with flat inox frame.

Up To 1,600 Cans Per Hour

[1] Double-phase Linear Electro-pneumatic Rinser-Blowers

There are 6 electro-pneumatic rinser-blowers suitable for cans with maximum diameter of 85 mm. Empty cans are grasped by a pincer and turned upside down where a nozzle enters the can approximatedly 15 mm. There are two injection circuits the duration of injections is adjustable through control panel and the operation occurs only when the can is present. The air injection substantially reduces the water residue in the can.

[2] High Pressure Linear Electro-pneumatic Filler

6 electro-pneumatic filling valves for cans with maximum diameter of 85 mm. (3.3 inches).

Each valve includes:

- Can presence sensor.

- Pressure transducer to control the pressure in the can (the valve does not start filling if the can does not reach the tank pressure)

- Electro-pneumatic valve on each spout, to allow, if the can is present, the injection, the pressure compensation, the auto-levelling and de-gassing.

- Double effect electro-pneumatic piston on each valve for gas injection circle opening and closing.

- Double effect electro-pneumatic piston on each valve for gas returning circle opening and closing.

- Double effect electro-pneumatic piston on each valve to liquid circuit opening and closing.

The filling level is centralized and manually adjustable. Every valve disposes of dummy can with manual positioning for the filler washing and sterilization. The valve can work both with sparkling liquid with pressure up to 4 Bar and with still liquids up to 0 Bar. The filling level is precise even without the levelling operation. The complete closure of the filling valve greatly improves the degassing even with difficult products. The filling valve is under patent. All circuits are canalized (even the degassing one) and the filler is set for a sterilization CIP system. The feeding from the bottom allows a natural and total emptying of the tank. The flow is adjusted by an electro-pneumatic valve. The injection phase before filling allows to replace the air in the can with neutral gas; in this way the oxygen contained in the can is eliminated. The gas pressure in the tank, the injection one and the one of the levelling circuit are handled by PLC. The pressure of the cans lifting pedestals is handled automatically by PLC. The filling valve is under patent.

[3] Linear Lid Dispenser with Gas Injection.

The lids are singularly released from the loader and dropped on a side shifter. The side shifter moves all the lids simultaneously above the cans. The lids are collected by the gripping devices and, after the retreat of the side shifter, laid on the cans with a light pressure. The gas injection heads, placed near the extremities of the cans, allow to inject neutral gas into the headspace during the phase of distribution and laying of the lids. The injections duration is adjustable through control panel and performed only when the can is present. The neutral gas injection substantially reduce the oxygen quantity in the space underneath the lid.

[4] GAI 4310L Single-Head Seamer.

A single head seamer made of Stainless steel to seam the lid. The intermittent star moves the can on the lifting plate, which lifts it and brings it next to the rotating spindle. While the can turns, the two rollers seam it. All operations are controlled by mechanical cams.

Description

TECHNICAL DATA:

- Production Speeds: up to 1,600 cans/hour (on 0.33 cl. standard can)

- Electrical height adjustment of all stations (rinser, filler, can lids dispenser and seamer).

- Equipped for a cylindrical bottle.

- The monoblock is equipped with:

- Safety guards in accordance with CE standards with tempered glass doors;

- Universal infeed screws;

- Dummy can for rinser sterilization;

- Dummy cans for filler sterilization;

- Dummy cans for sterilization of the gas injection station and foaming jet;

- PLC and operating terminal (touch screen);

- Weight control with expeller;

- Cans washing at the monoblock outlet with 7 nozzles outside protections with dripping on the frame;

- Belt start: 500 mm

- Belt end: 500 – 0.5 mm

- Can Diameter: 50 – 85 mm

- Output: 650 liters/hour